-

Shop All Products

-

-

Shop All Products

We meticulously sculpt and construct each model by hand to ensure our customers have durable shower units they can comfortably rely on for years to come.

-

-

-

About

-

-

About

We strive to be world-class in everything we do by hiring the best people, building the best product, and providing the best customer experience.

-

-

- Who We Work With

-

Resources

- Projects

- 503-303-3300

- Contact Us

- Search Products

Blog

Discover the latest industry trends and insights related to bathroom architecture and ADA compliance.

Strength-Testing is a Crucial Step Toward an ADA Compliant Shower

If you want to have an ADA compliant shower, you need to make sure the unit(s) you purchase are correctly strength tested. Whether it’s meeting the ADA grab bar requirements or the durability of the shower bottom plate, every compliant unit has to prove itself to withstand the proper amount of weight and wear-and-tear.

To help you identify the difference between an ADA compliant shower and a non-compliant unit, here’s how and why strength-testing plays a vital role in ADA shower requirements.

The Strength Requirements for an ADA Compliant Shower

Most of the ADA requirements for strength and durability in a shower depend on the grab bars and seats located in the unit. Shower seats and grab bars, for example, have to be able to withstand up to 250 pounds of weight.

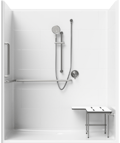

To ensure that our products were fully compliant with these requirements, EverFab had Carlson Testing Inc (CTI) perform a load-bearing test on the factory-installed grab bars and seat on the ADA compliant shower model S3839A and both the factory and field installed grab bars on the ADA compliant tub shower model TS6032A.

Both products were proven to be ADA compliant by a large margin. The factory assembled units supported at least 2x the ADA requirements. In one test the grab bar supported as much as 1500 lbs! The test results allow EverFab the privilege and opportunity of showcasing our shower and tub units as being fully compliant with the strength requirements outlined by the ADA.

Designing a Better Shower Bottom Plate

EverFab’s team of bathroom artisans didn’t stop there, though. To ensure that our units are more durable than anything else on the market, we’ve designed a better kind of shower bottom plate to prevent cracking or damage. While not required per the ADA, bottom cracking is one of the most common failure points in showers, and we wanted to make sure our units were an exception.

Pre-leveled and diamond cut on a custom machine in our factory, EverFab’s bottom plate is constructed of the same composite material we use in all of our shower and tub units. And since we laminate the shower bottom plate onto the unit, it’s proven not to break off, bend, or sag over time or if left outside for prolonged periods.

Where Does EverFab’s Shower Strength Come From?

EverFab’s showers are some of the most durable fiberglass shower units out there, and the reason for that comes down to the shower materials we use in our construction. Instead of relying on wood or cardboard, as other shower manufacturers often do, we use a specialized material that won’t swell or distort the way cheaper, lighter materials will.

Additionally, the EverFab Core Material we use in our shower units is 50% lighter than a plywood-backed alternative—making it easier to transport—without sacrificing any of the strength that users rely on. Similar materials are used across the fiberglass industry and can often be found reinforcing boat hulls, bus exteriors, and a wind turbine's blades.

This is why we’re proud to offer a 30-year warranty on all our units; that’s how confident our craftsmen are in the shower and tub units they make by hand.

If you have any questions about the strength-testing process used for our ADA compliant shower units or want to learn more about our products' durability, don’t hesitate to get in touch with one of our experts today!

Get the latest!

Subscribe to our newsletter

Read On

The Best Bath Tub-Shower Has These 5 Qualities

When it comes to fiberglass, the best bath tub-shower models emphasize efficiency, durability, and...The 5 Best Bath Qualities to Look For in ADA Compliant Showers

ADA compliance standards are important for ensuring reliable and accessible facilities, but the...The 5 Features You Need In a Safe Shower For Seniors

Safety is a core concern of accessible shower design for senior living facilities and assisted...9050 Porter Way SE, Aumsville, OR 97325

COPYRIGHT © 2025 EVERFAB