-

Shop All Products

-

-

Shop All Products

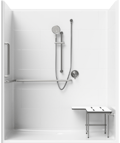

We meticulously sculpt and construct each model by hand to ensure our customers have durable shower units they can comfortably rely on for years to come.

-

-

-

About

-

-

About

We strive to be world-class in everything we do by hiring the best people, building the best product, and providing the best customer experience.

-

-

- Who We Work With

-

Resources

- Projects

- 503-303-3300

- Contact Us

Blog

Discover the latest industry trends and insights related to bathroom architecture and ADA compliance.

Shower Bottom Weak Points (And How to Prevent Them)

The shower bottom plate is the most common point of failure in a prefabricated shower unit — but it doesn’t have to be. With proper care and precaution, you can prevent the shower from exhibiting any weak points or suffering damage during delivery, installation, or years of use.

5 Potential Shower Bottom Weak Points

-

A low spot or high spot in the shower pan

This common problem happens when the subfloor or support system beneath the shower bottom is not evenly sloped and the pan itself is flexible. Unfortunately, this often goes undetected until after shower base installation. Even a slight bump in the center of the shower floor can cause real trouble if the drain is beneath the showerhead on one end, as it can trap water on the other end of the unit or cause overflow if the threshold is low. Correcting the low or high spot after installation is not simple.

-

Wood shims

Shims are a common solution to gaps between the shower base or support ribs and the subfloor or mortar bed. Shimming these small spaces with wood can add support and reduce flex, but it creates other weaknesses. It’s hard to determine the perfect thickness for each wooden shim, and uneven support (or over support that lifts the shower bottom in some areas) is asking for trouble. Furthermore, wood shims can gradually rot and collapse if exposed to water or moisture.

-

A pulverized mortar bed

Every shower unit should be rated to support a specific maximum weight. Don’t let the presence of a mortar bed lull you into complacency. Exceeding safe recommendations with very heavy usage can cause a mortar bed to crack or crumble over time, and a pulverized mortar bed leads to structural failures.

-

Leaky drain fittings

More often than not, leaks around the drain are due to severe shower base flexing, which distorts the shape of the opening for the drain and can create leaks or damage around the drain fitting. It’s a sign of a poorly supported shower base or extremely thin and flimsy shower pan material.

-

Wood or MDF (Multi-Density Fiberboard) reinforcement

Some acrylic and fiberglass shower units use heavy wood or fiberboard reinforcement to add rigidity to the shower bottom. It would look something like the picture below:

This may seem like a good idea compared to thinner, unreinforced bases that require installers to create a supporting sub-structure or lay a mortar bed to support the shower floor. However, these materials add unnecessary weight to the shower unit and can swell, rot, or warp if ever exposed to moisture. They’ll also prevent the layers of fiberglass or acrylic from properly bonding and can lead to delamination or separation over time.

How to Prevent a Weak Shower Bottom

-

Ensure that the subfloor or mortar bed is level and consistent

As the saying goes, measure twice, cut once. Extra care pre-installation will save a lot of headaches in the long run. A reliable and perfectly level surface for the shower unit is the best way to prevent complications with a prefabricated shower bottom.

-

Use plastic shims to accommodate for an uneven subfloor

If you must shim, use plastic. It won’t rot, swell, or disintegrate if exposed to water. However, this is still a less than ideal solution when a more consistent floor or perfectly leveled shower base would ensure even contact between the shower and the supporting surface.

-

Check the shower’s weight limit and follow it

A trustworthy manufacturer will put their showers to the test and report reliable and safe weight limits. Look for a shower bottom that’s made with durable and resilient materials and has the strength test results to prove it. Make sure to respect the limits verified in those tests.

-

Avoid thin, unsupported shower bases

Many manufacturers ship their units with thin bottoms and no built-in supports, leaving it to installers to painstakingly lay and level a mortar bed or construct their own support structure. Others are supported with cost effective but insufficient wooden or PVC legs. The manufacturer may be saving money, but you won’t if this leads to leaks or cracks. Evaluate your options carefully and opt for a unit with a shower bottom that’s thick enough to prevent severe flexing in between support points or around metal fixtures.

-

Invest in a better bottom plate

Wood and MDF reinforcements are heavy and create their own liabilities. EverFab’s shower bottom was designed specifically to address the common and costly weaknesses in fiberglass shower floors. Our showers use a durable, thick, one-piece composite (with the same durable EverFab core material used on the rest of the shower) with multiple touchpoints on the floor to support the shower. It’s fully laminated onto the unit base, pre-leveled, and diamond-cut for perfect balance and strength.

Get in touch with the EverFab team to learn more about our popular and industry-leading shower bottom design that won’t sag, crack, or break. We’d love to work with you on your next shower project.

Get the latest!

Subscribe to our newsletter

Read On

Avoid Delamination with EverFab Commercial Shower Units

The commercial shower industry has a delamination problem. Heavy, cheap plywood backing is common...How Can You Tell Which Shower Materials Are the Best?

Stone or tile showers can be beautiful, but also tend to be heavy, expensive, time-consuming to...How Senior Living Developers Maximize Their Budget For Shower Units

Selecting a shower for seniors requires careful attention to compliance with ADA standards and...9050 Porter Way SE, Aumsville, OR 97325

COPYRIGHT © 2025 EVERFAB