-

Shop All Products

-

-

Shop All Products

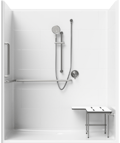

We meticulously sculpt and construct each model by hand to ensure our customers have durable shower units they can comfortably rely on for years to come.

-

-

-

About

-

-

About

We strive to be world-class in everything we do by hiring the best people, building the best product, and providing the best customer experience.

-

-

- Who We Work With

-

Resources

- Projects

- 503-303-3300

- Contact Us

- Search Products

Blog

Discover the latest industry trends and insights related to bathroom architecture and ADA compliance.

5 Benefits of a Fiberglass Shower Base

.jpeg?width=951&height=713&name=shower%20base%20(1).jpeg)

For senior living architects complying with ADA shower requirements, installation errors can be extremely costly. Not only do these errors waste time, but the threat of severe water damage is a constant concern. This issue is only exacerbated by the fact that most shower manufacturers use plywood or cardboard backing. EverFab addresses this long-standing industry issue with its proprietary Core Material, its innovative lamination process, and its unique shower bottom plate.

According to the CDC, one in four (27%) of Americans have some form of disability with 12.1 percent having serious mobility problems. Water damage resulting from poor shower installation isn’t just a cost concern; excessive water and leakage can lead to serious slips and falls, or worse, death. The goal should always be to install a shower you’re confident will last and survive the elements.

So, what are the benefits of EverFab’s fiberglass shower base?

1. Improved Chemical Bond

Plywood is a hygroscopic material which means it easily absorbs moisture. While it may be a cost-effective material for most shower manufacturers, once it absorbs moisture, it swells. When it loses moisture, it contracts. Since wood expands and contracts when exposed to different temperatures, this constant swelling and contraction leads to bending, distortion, and rotting until delamination between layers occurs.

EverFab bypasses plywood altogether. Instead, EverFab uses its Core Material as its main reinforcing material. This durable, high-strength Core Material is a proprietary hexa-comb fiberglass mesh that actually improves the chemical bonds between all composite layers. Unlike plywood, our fiberglass shower base won’t absorb moisture and will never swell or bend.

2. Lighter Shower Unit and Faster Installation Times

Manufacturers that use plywood, cardboard, or even PVC end up increasing the weight of their shower units. This increases transportation costs and means shower installation times are longer. EverFab’s Core Material and proprietary process uses a higher volume of glass and a lower volume of calcium sulfate. This leads to shower units being 50 percent lighter than manufacturers using plywood or cardboard which translates to lower transport costs and faster installation times.

3. Durable, High-Strength Shower Units

Manufacturers that use cardboard, plywood, or PVC tend to equate high weight with higher strength. Unfortunately, that’s simply not the case. While wood-backed shower units can exceed 400 pounds, EverFab’s fiberglass and Core Material-backed shower units average just under 150 lbs.

For EverFab, it’s not enough just to meet the ADA standards and regulations governing the load tolerance for ADA-compliant showers. We went a step further by submitting our fiberglass shower base to extensive compression and load testing at an independent third-party testing laboratory.

Results showed that our core material and shower design withstood more than twice the ADA threshold for load tolerance. In addition, our shower grab bar was able to withstand up to 1500 lbs where the ADA requirement for compliance is only 250 lbs. Not only are our showers more than half the weight of wood-backed competitors, but those competitors would be hard-pressed to match the load tolerance of our shower designs.

4. Long-Lasting Service Life

In the end, it’s all about installing ADA-compliant showers that stand the test of time. Every EverFab shower is a one-piece shower unit comprising our Core Material and full laminated bottom plates. This means you’ll never encounter any gaps or voids during installation the way you would multiple-piece shower units. Those gaps can quickly lead to rot and mold that propagates underneath and behind the multi-piece shower layers.

5. Improved Customer Relationships

As a senior living architect, you’re only as good as your last job. It’s the reality of working in today’s ultra-competitive market. Options abound and customers are always searching for the best service and highest value. Installing an EverFab fiberglass shower unit gives you the opportunity to explain to customers the high-quality craftsmanship and attention to detail that goes into every EverFab product.

You’ll gain instant credibility when explaining the importance of EverFab’s Core Material, its custom lamination process, and the steps EverFab takes to ensure the highest quality shower unit. Customers want and need to know they’re paying for value and being able to demonstrate that value goes a long way to establishing your reputation.

Innovative Solutions from EverFab

EverFab has quickly established itself as an innovator, designer, and manufacturer of high-quality fiberglass shower units. The company’s commitment to manufacturing high-quality showers is backed by a committed and dedicated team of artisans, craftsmen, tradesmen, and design engineers.

If you see a shower unit that piques your interest or are looking for a custom-designed solution, contact us now.

Get the latest!

Subscribe to our newsletter

Read On

How EverFab Builds the Best Bath Systems for Senior Living Facilities

The design of the bathroom at a senior living facility plays a critical role in resident...What It Means to Be Handcrafted in Today's World

Think about how fast products are made, shipped, and received in today’s mobile economy. In a...The 5 Best Bath Qualities to Look For in ADA Compliant Showers

ADA compliance standards are important for ensuring reliable and accessible facilities, but the...9050 Porter Way SE, Aumsville, OR 97325

COPYRIGHT © 2025 EVERFAB